Vacuum coating for better liquid intrusion

In production of pet food diets made from extruded pellets, there has been a great development over the past decade. An important part of the development is the addition of different liquid additives such as digest improver, vitamins, fat and appetite improver to mention a few.

Palatability is a key factor in producing high quality pet foods. Besides involving a careful selection of ingredients, it involves the right processing technique. The multiple layer coating possibility ForbergSRTmRVC (Rotating Vacuum Coater) gives, has an important impact on food quality.

Forberg International AS has been at the front line of vacuum coating ever since the process was introduced to the industry making pelletised fish feed in the beginning of the nineties. This technique has made it possible to increase the level of energy in the feed to new and higher levels.

It is of great importance to keep the pellets dry on the surface even after adding the different liquids and the process of vacuum assisted intrusion of liquid in the pellets is playing an important role.

RVC adapts to pet food market

To meet the requirements of the pet food market, some adaptations have been made although the dry product itself has many of the same physical properties as fish feed, at least concerning the ability to utilise the vacuum technique.

- The use of fat with melting point higher than ambient temperature has triggered use of special heat cable tracing of hoses to the nozzles, and even tracing of the nozzle assembly itself.

- Heat tracing and insulation of the coater body to prevent building up of solid fat in the machine.

- The machine housing and rotors can be made in stainless 304 or 316 depending on the level of acid addition.

Important features

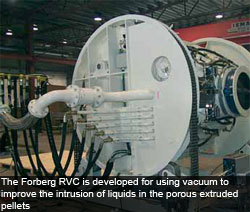

The Forberg RVC is a machine that is especially developed for using a vacuum to improve the intrusion of liquids in the porous extruded pellets. Important features of the improved RVC are:

- Loading and unloading of the machine through the same valve minimises the risk of leakage;

- The loading/unloading valve is out of the process area during the actual process, ensuring that what is put into the machine stays there until the charge is ready for unloading;

- Smooth process chamber with accurately adapted rotors ensure very low wear and breaking of the pellets during the process;

- Total control of the vacuum cycle with regards to the rate of equalising back to atmospheric pressure gives an optimum capacity of inclusion;

- Easy to include Cleaning In Place (CIP) system for thorough cleaning in a fast and effective way; and

- Easy to change between formulas without the risk of cross contamination