Management strategies that can secure feed quality

Feed quality is influenced by many factors, from handling and storage of raw materials to the processing of feed. Controlling invisible quality parameters such as microbial degradation from bacteria and mould growth as well as chemical degradation due to autoxidation is often challenging.

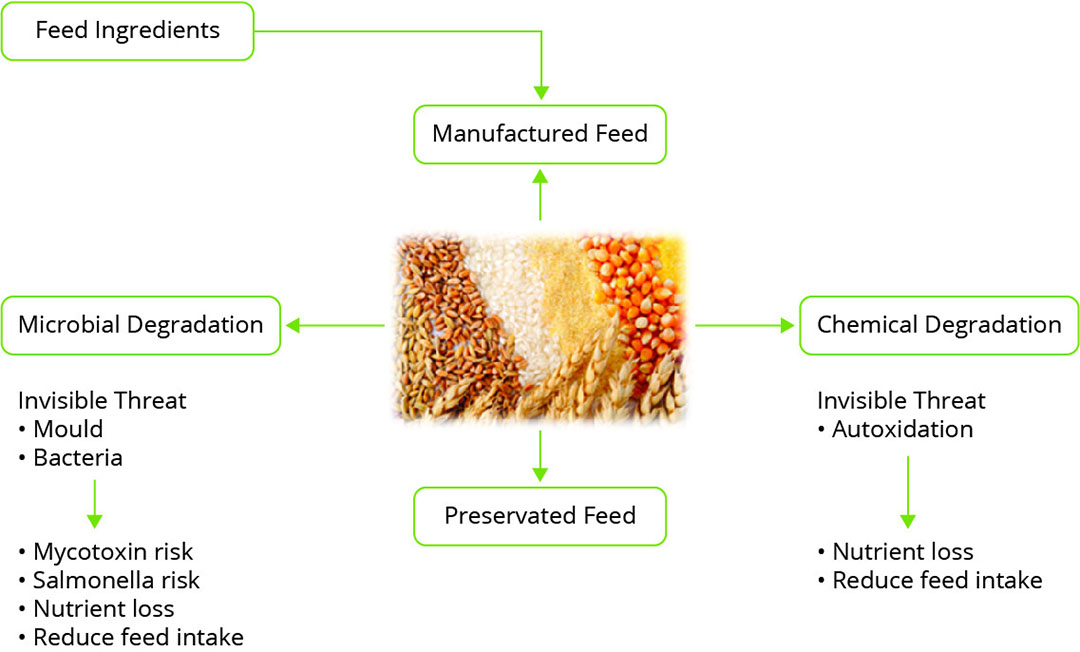

Feed is one of the most important inputs related to livestock production and profits. Succeeding or failing to improve yield depends therefore, to a large extent, on the quality of feed. Feed quality is generally perceived as the responsibility of both raw material suppliers and feed manufacturers, and it is affected by factors such as handling, storage, and use. Consequently, the objective of a feed quality assurance programme is to manufacture feed while guaranteeing that it is fit for purpose and of consistent quality. Providing high-quality feeds starts with ingredient sourcing and purchasing, which minimises safety risks in terms of microbial, chemical, and physical parameters. However, controlling some of the invisible microbial and chemical quality parameters is often difficult and challenging. To help with this, quality control should prescribe specific assurance-preservation programmes both for feed ingredients and for finished feed, depending on the relative risks. This article discusses autoxidation as a chemical quality parameter and mould growth as a microbial quality parameter (Figure 1).

Figure 1 – Feed quality degradation pathways.

Feed ingredients and risk assessment

The risk factors associated with fresh and stored feed ingredients, as well as finished feeds, are well understood but often overlooked. Assessing feed ingredients and feeds based on their high, intermediate, or low risk helps us to make decisions about which actions to take to mitigate variations in quality. Table 1 shows an example of a risk assessment chart. It indicates key factors that contribute to the oxidative damage of fats/oils and fat-soluble nutrients (i.e., oxidative quality), and those that favour the development of mould and other pathogens (i.e., microbial quality).

Table 1 – Risk chart for feed ingredients and finished feeds.

Assurance programmes and preservation solutions

High-quality finished feed retains its nutritional value and visual appearance from the day it is produced until the day it is consumed. Maintaining the nutritional value and quality of feed ingredients takes more than just proper handling and storage. Various practices should be implemented to preserve and guarantee feed ingredient and final feed quality. For example, controls include:

Storage quality and hygiene

Ideally, storage structures should be clean, dry, and well ventilated. Equipment should also be regularly cleaned and old feed residues must be removed. It is important to periodically schedule inspections and repairs of storage structures (i.e., roofs and walls) and implement pest control to ensure that storage structures remain in good condition.

The use of mould inhibitors and antioxidants in accordance with relative risks

The quality of ingredients and final feeds is determined not only by their nutrient composition, but also by their hygiene or microbiological loads, which involves looking at the number of mould spores (this is a particularly important factor). Under field conditions, before harvest, little can be done about mould contamination and its subsequent toxin production. However, we can adopt several post-harvest strategies to control the growth and development of moulds and reduce their negative impact on feed quality.

Firstly, mould inhibitors can be applied to control mould growth, and therefore mycotoxin production. Adisseo has cost-effective solutions for grain treatment and feed storage to prevent mould growth which are available in both liquid and dry form and formulated with a unique synergistic, buffered blend of propionic and other organic acids to effectively combat moulds. The use of mould inhibitors is proven to prevent mould contamination in feed ingredients and feed, preserve their nutritive value and ensure safe-handling during short and long-term storage.

Secondly, we also need to prevent oxidative degradation in feed ingredients and final feeds. Oxidized fats carry aldehydes and peroxides that are harmful to animal immunity and detrimental to gut health. Adisseo has developed an efficient strategy to prevent the oxidation of lipids or feeds by combining ingredients with varying strengths and applications, with proven efficacy in controlling different parts of the oxidation cycle. Through its proprietary formulations and manufacturing processes, Adisseo provides a programme with antioxidant solutions in both dry and liquid forms. This programme maximises the synergistic effect of selected antioxidant compounds and offers an ideal antioxidant solution for fat-rich feed ingredients (i.e., pigments and vitamins) and final feeds.

A systematic approach

Good manufacturing practices are vital and should focus on minimising the risk factors that impact product quality and safety. Invisible threats include microbial degradation from bacteria and mould growth, as well as chemical degradation by autoxidation. These degradation processes pose the threat of nutrient losses and reduced feed intake, not to mention mycotoxin production and other contamination risks. A systematic approach to managing these threats must be developed, including a risk chart per ingredient and per type of finished feed. It should be based on their specific characteristics and risk for microbial and chemical degradation. This approach lays the groundwork for implementing good management practices and appropriate preservation procedures according to the level of risk. An important action can include the addition of appropriately formulated antioxidants and mould inhibitors with a dose rate in line with the risk profiles of the specific ingredients or finished feed.