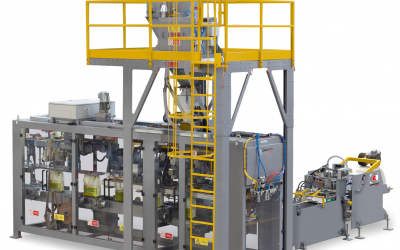

Dinnissen launches ultra dust-free bag emptier

Dinnissen Process Technology has developed a new bag emptier for automatically emptying bags containing hazardous powders, particles or granulates. The new version reduces the quantity of material released into the environment to an absolute minimum.

The bag emptier is a new version of Dinnissen’s classic Dima 200 and makes it possible to automatically empty bags while releasing less than 0.1 mg of dust per m3 of discharged material. The ultra dust-free bag emptier is suitable for discharging extremely fine particles (powder particles down to 10 nm).

The new version has an exclusive double filter in combination with powerful suction and a special dust-free seal for the air exhaust. The very smoothly polished interior of the bag emptier simplifies cleaning and prevents particles from being left behind in the machine.

The ultra dust-free bag emptier is also based on an easy-to-clean-concept, making quick and efficient cleaning possible. It is fitted with a fully automatic cleaning-in-place concept based on air and suction which practically eliminates the need for any human intervention during the cleaning process. Depending upon the specific situation, the ultra dust-free Dima 200 can process from 1 to 160 bags per hour. It is presently being applied in the chemical and pharmaceutical sectors.

Related website:

Dinnissen