New roller mill ups Farmers Co-op productivity

A new roller mill will double the corn grinding capacity at Farmers Co-op Elevator Company’s Houston, Minnesota, USA, feed mill.

“It was time to replace our old roller mill. It was more than 30 years old and had probably outlived its usefulness,” explained Farmers Co-op Elevator Feed Division Manager Rod Torgerson.

The triple roller mill improves the quality of corn ground. Installation began on April 23 and was completed in early May.

Farmers Co-op made a significant investment that will give customers better quality cracked corn. They invested in the larger, higher quality mill to provide a better product, improve feed mill efficiency, and meet customers’ growing needs.

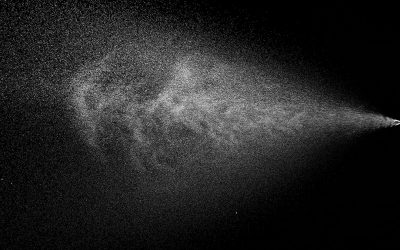

The new roller mill has three sets of rollers and requires three 50-horsepower motors to run it. The additional set of rollers makes a finer grind possible and allows more control over the size of the grind.

According to Torgerson, fine ground corn will be 500 microns, 200 microns finer than the old roller mill allowed. That means the corn will be more available and easier for livestock to digest.

The mill also has a two-way switch that allows operators to set rollers at the same speed to create a better quality cracked corn with fewer fines.

Bottleneck

With a grinding capacity of 25 tonnes per hour (nearly 900 bushels per hour), the new mill nearly doubles the capacity of the old roller mill.

The old roller mill was a bottleneck in the feed manufacturing process. With the increased capacity, the entire mixing process will be more efficient.

Not only is it more efficient, with its sealed, dust-proof design, the dust and noise in the feed mill are minimized, which improves working conditions for all of the mill employees.

“We’re always trying to increase efficiency to keep our costs and prices to the customer down and provide a better quality product,” Torgerson added. “Investing in this new equipment helps us do both.”

Farmers Co-op Elevator Company is a member-owned cooperative serving farmers, rural households, gardeners and animal lovers in Houston, Fillmore and Winona counties in Minnesota and Allamakee and Winneshiek counties in Iowa.