Brewer’s yeast can help reduce methane production

Research shows that spent brewer’s yeast has the potential to curb methane production in the cattle industry.

Part of the Gut Health 2022 Special

Typically, brewer’s yeast is discarded once it’s been used, but sometimes it’s added to livestock feed as a source of protein and nutrients. According to a team of scientists with the Agricultural Research Service (ARS) in the US, as well as Warren Wilson College and Asheville Sustainability Research, spent brewer’s yeast could also help reduce methane production in cattle. Research Leader of the Forage Animal Production Research Unit at ARS, Michael Flythe, explains what their research uncovered and how it could be practically applied by the cattle industry.

Greenhouse gas emissions

In the US, agriculture accounts for 11% of all greenhouse gas emissions. Ruminants are responsible for about a quarter of that total. Researchers believe that by optimising fermentation, growth and milk production will be safeguarded – even helped – and impact on the environment could be minimised. One of the ways this has been done in the past is through the use of ionophore antibiotics, such as monensin.

“They‘re not really particularly clinically relevant, so we don’t have many applications for them in human medicine, so that makes them a good candidate,” Flythe explains.

While monensin worked to promote growth by enabling better access to nutrients that in turn boosted feed efficiency, it also inhibited specific microbes in the rumen. Some of those bacteria play an important role, particularly in high-forage diets where cattle don’t have the enzymes they need to break down cellulose. But others carry out very wasteful processes. Methanogens, for example, convert carbon into methane, and ‘hyper-ammonia-producing bacteria’, also known as HAB, break down protein and amino acids into ammonia, which is converted to urea and expelled as nitrogen in urine.

Antibiotic resistance

Methane and ammonia are not only harmful to the environment, but also rob the animal of valuable amino acids that are critical for growth and milk production. But overuse of antibiotics can lead to antibiotic resistance, and as such, all non-prescription antibiotic use has been banned in the US, meaning monensin could no longer be used to promote growth or inhibit microbial communities in the rumen. Researchers have been searching for other options since.

“Not all of us wanted to give up on it because this idea of growth promotion and feed efficiency is still a very good idea,” says Flythe. “But using antibiotics is a bad idea.”

Plant compounds

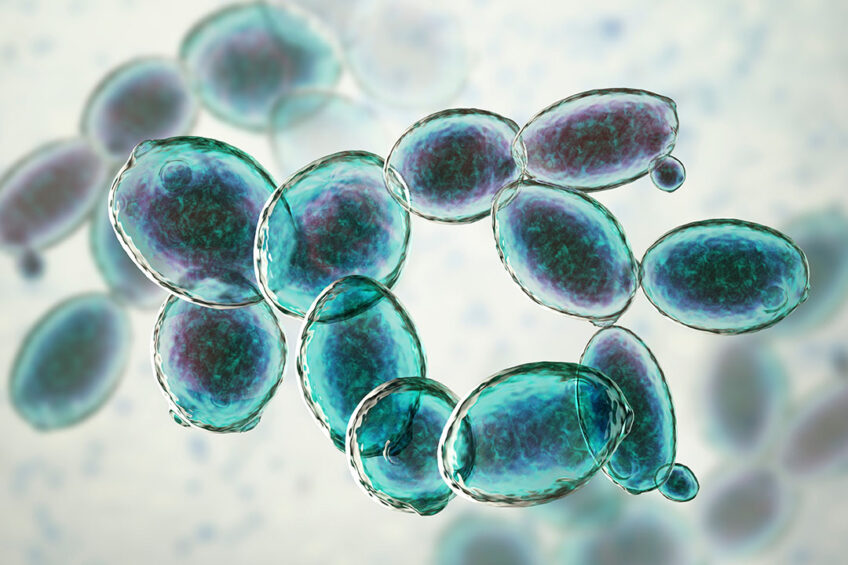

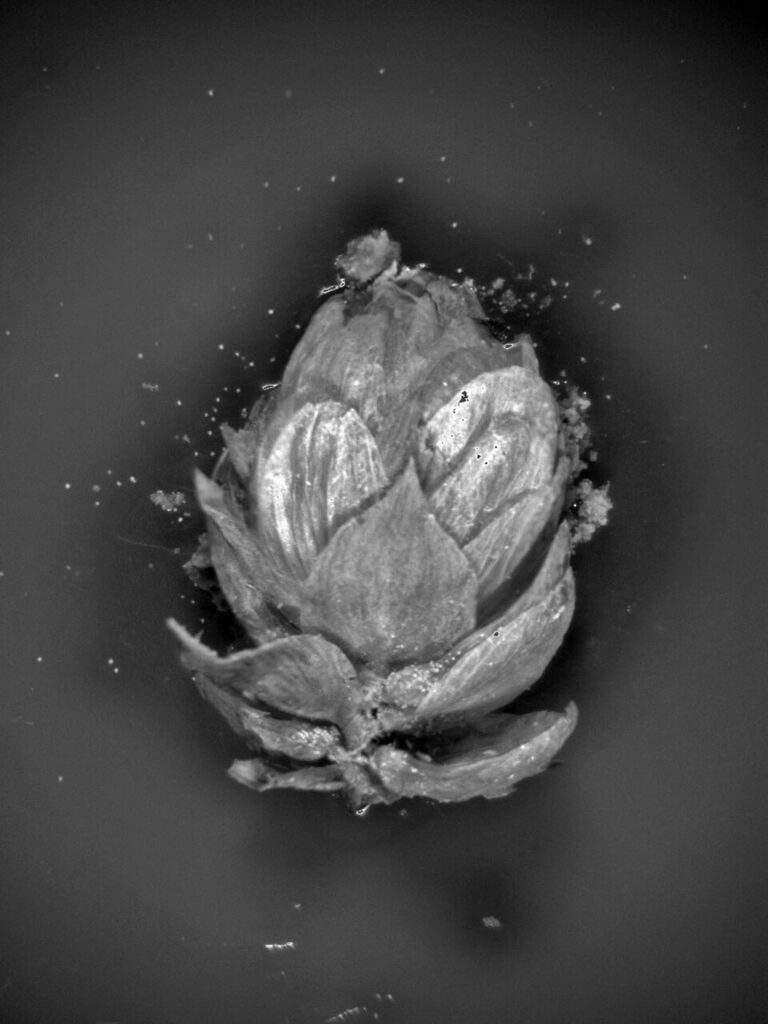

The need for new options that behaved like antibiotics without being antibiotics paved the way for researchers like Flythe to explore plant compounds. One of those plant compounds is leftover brewer’s yeast. During the brewing process, a yeast known as Saccharomyces cerevisiae absorbs humulones, lupulones and other compounds from hops.

Humulones and lupulones works well as an antimicrobial as they kill some of the same microorganisms that monensin kills. They also have the added benefit of being non-toxic. Flythe was able to show that lupulone prevents the growth of HABs, thereby preventing the production of ammonia in ruminants, but the problem was that hops are expensive.

“It was never cost effective to give it to cattle, and so eventually I gave up and I moved on to other things,” Flythe says.

Potential of spent brewer’s yeast

Years later, Flythe received a call from Rusty Bryant, a retired chemist and research development consultant with Asheville Sustainability Research in North Carolina, a region known for its craft breweries. Bryant was trying to find ways to incorporate brewer’s yeast into food products. But while they’re high in protein, they added a bitter taste to the baked goods he was making.

Bryant wanted to understand what was behind the bitter taste so he sent the spent brewer’s yeast off for evaluation. That’s when he noticed the high concentration of alpha and beta acids from the hops. Curious, he dug into the literature and stumbled upon Flythe’s older work and quickly realised there was potential to use spent brewer’s yeast instead of hops as a means of inhibiting the production of bacteria that carry out wasteful processes in the rumen.

The idea sounded solid, but Flythe and Bryant needed to test their hypothesis in the lab. To do this they took samples of spent brewer’s yeast used in 6 different kinds of beer at a local brewery and added them to flasks containing live cultures of either methanogens or HAB. What they observed was a direct correlation between the concentration of hops compounds in the spent yeast and the amount of gas produced, as in the compounds from the hops inhibited the production of both methanogens and HAB. On average, the spent brewer’s yeast curbed the microbes’ production of methane by 25%, a number that brings it pretty closely to the efficiency of monensin. On top of that, spent brewer’s yeast is non-toxic and a good source of protein.

Enough brewer’s yeast generated

Once solutions do come to market, there will be plenty of spent brewer’s yeast at their disposal. One estimate suggests that the brewing process generates 15-18 tons of spent brewer’s yeast per 10,000 hectolitres of finished beer. Another study suggests brewers in the European Union alone generate 1 million tons of spent brewer’s yeast annually.

To use it as a livestock feed additive would require processing, though.

“I think that the breweries need to really think of their waste streams as co-products,” Flythe says. “There are some engineering challenges that I think are going to have to be addressed by process engineers related to how breweries will bring this online.

“I’m there to support them, as are other folks at USDA ARS,” he concludes.